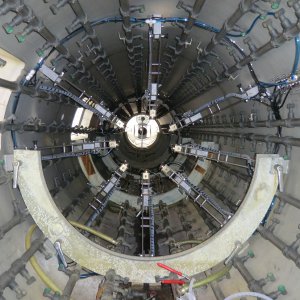

The ConPro Measuring arm system (MA-S) permits a faster and more economic start-up process during production of thick-walled large-diameter pipes. This is realised by ultrasonic sensors which measure the wall-thickness distribution precisely and automatically, instead of former difficult and time consuming applications. Advantage for the operator: The pipe can be centered immediately at the die.

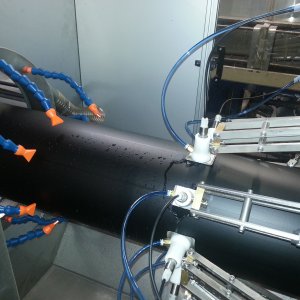

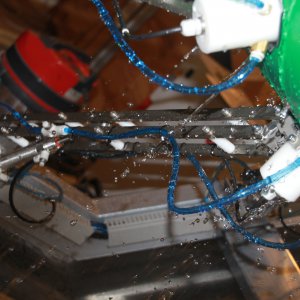

After start-up of the line, the ultrasonic sensors will be set to the pipe pneumatically and the measuring of high-definition ultrasonic electronic starts. To evaluate measuring data immediately, the results will be shown graphically at a 15” touch-display. Potential differences of wall-thickness distribution will be evident promptly. Standard measuring with 8 sensors.

Result of early control: The pipe can be centered after production of a few meters only and start-up scrap will be reduced obviously. The SoniCon-SL/MA-S system amortizes itself within a few months.